Manufacturing Technician

| Department: Manufacturing | Reports To: Manufacturing Manager |

| Prepared: 10/25/2017 | Status: Non-Exempt / Hourly |

| SUMMARY

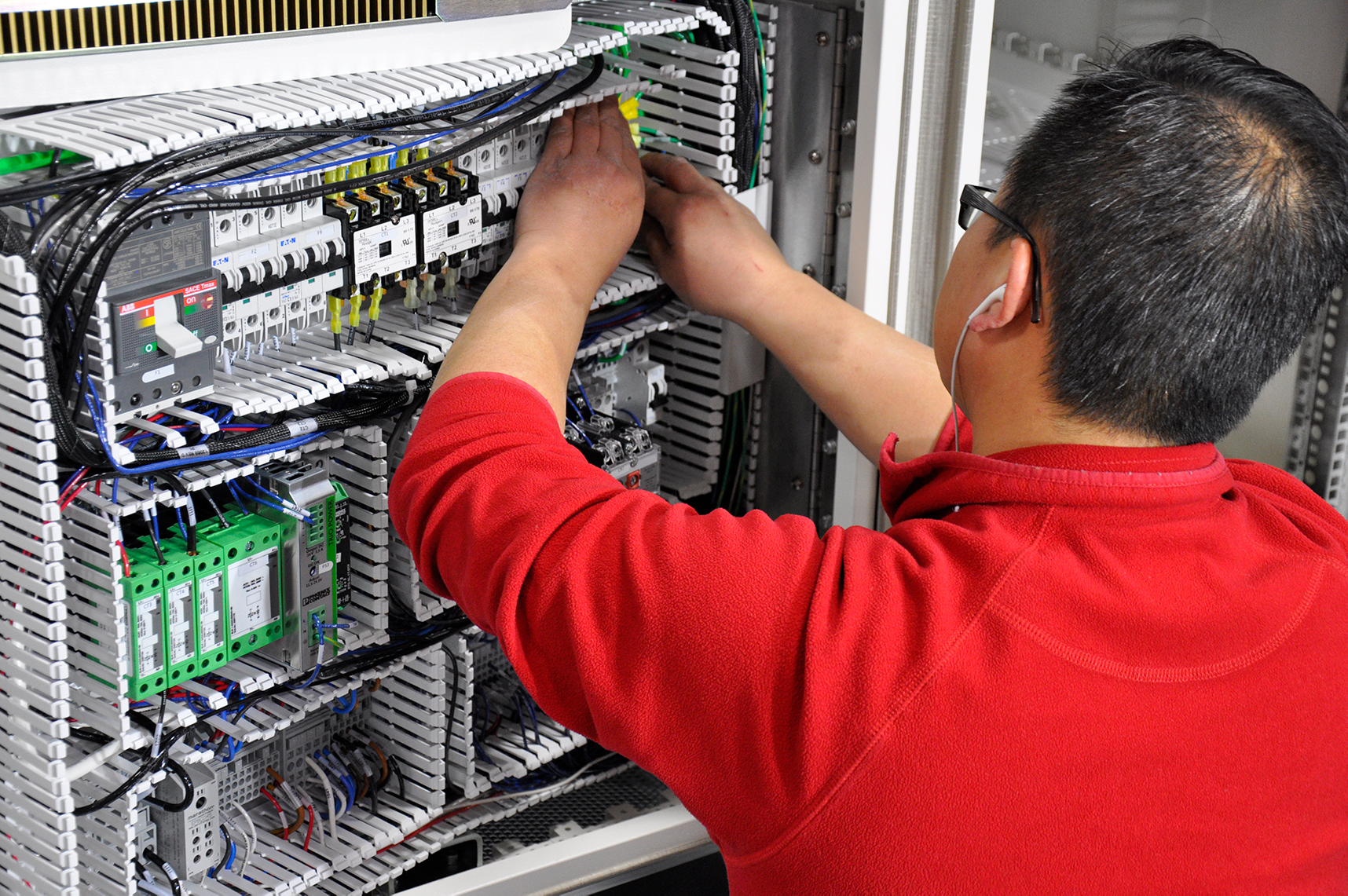

Under the direction of a Manufacturing Manager, the Manufacturing Technician is responsible for assembling; performing test sets and checking devices to ensure correct operation and will need to make necessary calibrations and configuration changes to regulate components in accordance with prescribed procedures and correct operation; inspecting for correct assembly and repairing assemblies. ESSENTIAL DUTIES AND RESPONSIBILITIES This list of duties and responsibilities is not all inclusive and may be expanded to include other duties and responsibilities as management may deem necessary to meet the needs of the organization from time to time, as needed.

QUALIFICATIONS To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. Requires High school diploma or equivalent and some prior work experience, preferably in a manufacturing environment or in a work environment employing one or more of the following skills: computer assembly, soldering, cable harness, electrical panel wiring, plumbing. KNOWLEDGE, SKILLS AND ABILITIES REQUIRED

PHYSICAL REQUIREMENTS AND WORKING CONDITIONS (The physical demands described here are representative of those that must be met by an Associate to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. The phrases “occasionally,” “regularly,” and “frequently” correspond to the following definitions: “Occasionally” means up to 1/3 of working time, “regularly” means between 1/3 and 2/3 of working time, and “frequently” means 2/3 and more working time.) While performing the duties and responsibilities of this position, the Associate is frequently required to stand and use hand(s) to operate tools and assemble parts. The Associate will occasionally talk and listen, climb or balance, reach above shoulders, bend at the knees or waist. H/she will frequently sit, walk, use hands to finger, handle or touch, stoop, kneel, crouch or crawl and move from place to place. The Associate must be able to regularly lift and move up to 50 pounds and occasionally up to 80 pounds. Specific vision requirements for this position include close vision, color vision and depth perception. |

|

| Interested in this position? Apply now. | |