About the GMI environment

- Team and family oriented philosophy throughout

- We make a difference by manufacture products for healthcare companies that save lives

- Plenty of on-site amenities and special events

- Work hard play hard mentality

GMI Solutions – Electro-Mechanical Manufacturing Engineer

SUMMARY

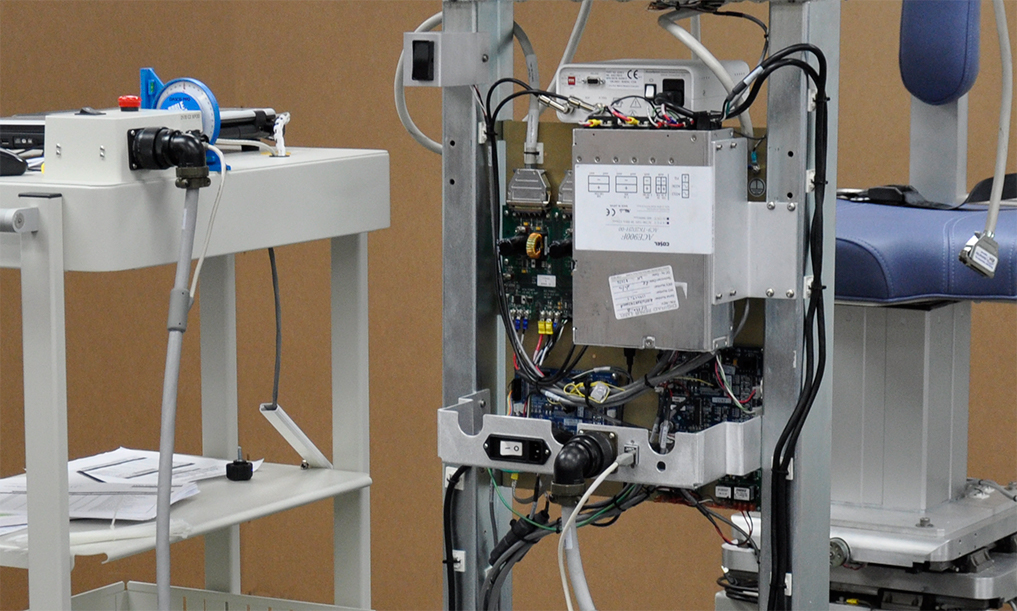

Under indirect supervision of the Manufacturing Engineering Manager, this individual performs and drives the support activities related to the manufacture and service of electro-mechanical assemblies and computer systems in one or more concurrent design and development activities; has direct interaction with many functional groups related to product design and manufacturing; directly supports the manufacture and service of products after production release; and performs related hands-on work as required.

ESSENTIAL DUTIES AND RESPONSIBILITIES

This list of duties and responsibilities is not all inclusive and may be expanded to include other duties and responsibilities as management may deem necessary to meet the needs of the organization from time to time, as needed.

Manufacturing / Design Interface

- Establish the build processes used in the manufacture of assemblies and embedded computers

- Develop bills of material with appropriate components for embedded compute solutions

- Understand computer standards to develop platforms that meet customer requirements

- Provide training on manufacturing and service processes

- Develop the repair processes used in the service of products

- Communicate the needs of the manufacturing processes to customer engineers

- Communicate the system design requirements from each project to manufacturing

- Find the best solution to meet the needs specified by the design while ensuring smooth execution in manufacturing

- Maintain documentation required to manufacture each product

- Provide input to the design process (may perform some CAD design of metalwork, cables, etc), verifies design output, ECO processing

- Labeling design and configuration

- Engage in continuous improvement, manufacturing efficiencies

QUALIFICATIONS

To perform this job successfully, an individual must be able to perform each essential duty satisfactorily. The requirements listed below are representative of the knowledge, skill, and/or ability required. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions.

Requires minimum of a Bachelor’s degree in an engineering related field or prior work experience, preferably in a manufacturing environment.

KNOWLEDGE, SKILLS AND ABILITIES REQUIRED

- Must be extremely flexible to changing requirements and be able to effectively multi-task between several concurrent assignments often with competing deadlines.

- Possesses the ability to lead and motivate groups and individuals. Able to think creatively and strategically to successfully mediate and negotiate with individuals and groups internally and externally. Able to overcome obstacles to cooperation and foster harmonious relations.

- Must be extremely organized and highly responsive.

- Able to work closely with cross functional activities throughout the organization.

- Requires excellent oral and written communication skills in order to interact professionally and courteously with other Associates and (vendors, customers).

- Provide assistance to other engineering projects and other departments as assigned.

- Must be responsible for proper handling of design data (confidentiality, properly filing of design data, etc.).

- Must be open and responsive to learning and developing new competencies both personally and for the organization.

- Must be supportive of continuous improvement within the department and individual processes.

- Must have the foresight to alert appropriate individuals of potential problems.

- Must have a positive, must do attitude and be willing to go the extra mile when necessary to successfully complete projects.

- Willing to travel domestically and internationally if necessary (infrequent).

PHYSICAL REQUIREMENTS AND WORKING CONDITIONS

The physical demands described here are representative of those that must be met by an associate to successfully perform the essential functions of this job. Reasonable accommodations may be made to enable individuals with disabilities to perform the essential functions. The phrases “occasionally,” “regularly,” and “frequently” correspond to the following definitions: “Occasionally” means up to 1/3 of working time, “regularly” means between 1/3 and 2/3 of working time, and “frequently” means 2/3 and more working time.

Must possess mobility to work in a standard office and lab setting and to use standard office equipment, including a computer, and to attend meetings at various sites within and away from the office. Strength to lift and carry materials weighing up to 80 pounds. Vision to read printed materials and a computer screen. Hearing and speech to communicate in person and over the telephone. Work is normally performed in a typical interior/office work environment, this position is factory based, in Mequon, WI.

We’re a medium size, family-oriented company that values our associates and are looking for your leadership to make a difference to the company’s overall success and we’ll be here to help.

If this sounds interesting, we want to hear from you!

If you have questions, feel free to email us at work4us@gmisolutions.com